Packaging film modifierTypical characteristics.1, generally used as packaging film material processing aids and material surface smooth function, improve surface glossiness; enhance the role of product packaging film surface and smooth; has a strong h…

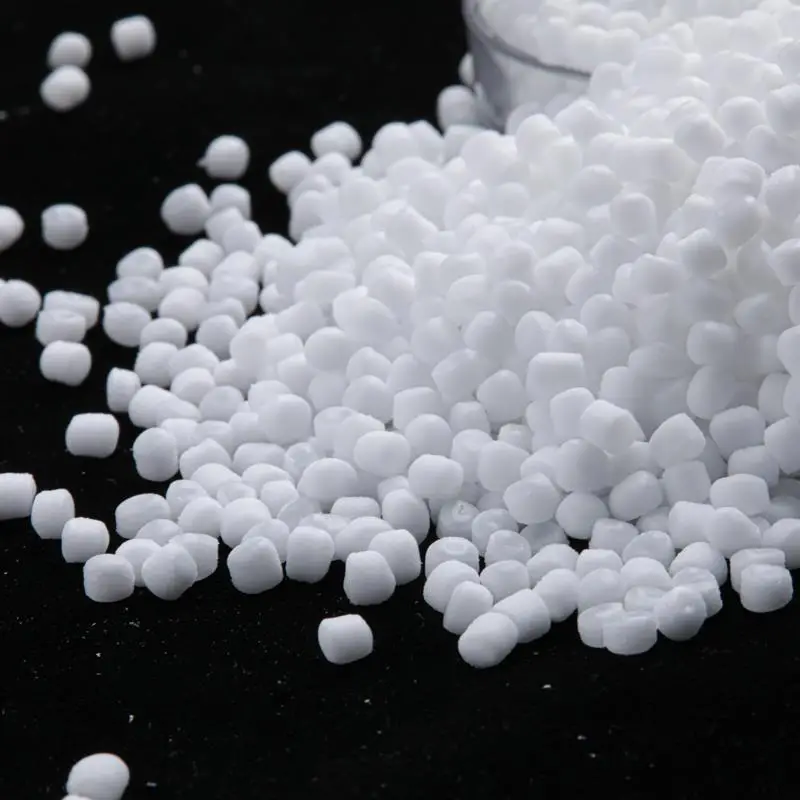

Packaging film modifier

Typical characteristics.

1, generally used as packaging film material processing aids and material surface smooth function, improve surface glossiness; enhance the role of product packaging film surface and smooth; has a strong high temperature stability.

2, with significant effect; and does not affect the mechanical properties of the product itself, use performance, appearance, as well as wrap and bonding properties; no effect on the performance of the film.

3, the two terminal active groups have strong reactivity, easy to react with TPE film, PP film, PE film, EVA film, BOPP cigarette film, food packaging film and other fields of a variety of materials, with better compatibility, easier to match and integrate with other polymer materials, with better stability and non-migration, not easy to precipitate, the surface will not produce a greasy feeling and bubbling phenomenon.

4, It can effectively reduce the film friction coefficient, improve plastic and raw material processing fluidity, reduce energy consumption, reduce torque, reduce equipment wear, improve production efficiency, reduce processing viscosity, and help film extrusion and demoulding.

5, and passed the EU SGS environmental protection certification, PAHS, ROHS, REACH, NP, phthalates and other environmental protection certification.

6, Based on the various characteristics of silanone functional materials, there are a wide range of shaping properties, if you need to use it for other purposes or solve other solutions, please test its feasibility beforehand; the Division will continue to strive to provide more information on the use of related products through improved technology.